Docks

EBDG excels in designing and analyzing marine structures, offering unparalleled expertise in drydocks, marine facilities and floating structures. Our depth of expertise ranges from basic design using regulatory formulas to first principle analysis utilizing advanced finite element analysis (FEA) to assess structural integrity, accounting for damage and corrosion effects. By utilizing state-of-the-art FEA, we provide cost-effective solutions that optimize structural repairs necessary to maintain or increase the lift load rating. Our engineers have hands-on shipyard experience and fully understand the operational aspects and structural behavior of drydocks. Our comprehensive services support drydock maintenance, capacity increase, and recertification, making EBDG a trusted partner in the marine industry. With a commitment to innovation and precision, we deliver robust designs tailored to meet the operational demands of floating structures.

Drydocks

EBDG's extensive experience with drydocks includes projects such as the design of a 220-foot drydock for Knight & Carver, capable of lifting 2,000 short tons, and ongoing support for Vigor Industrial's drydock maintenance program. Utilizing advanced FEA, we optimize structural integrity and minimize repair needs, ensuring compliance with NAVSEA standards. Our work with San Francisco Drydock #2 involved creating a Finite Element Model to support lifting large cruise ships, showcasing our ability to handle complex, large-scale projects with precision and efficiency.

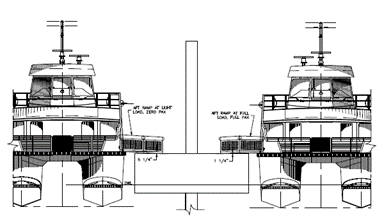

WETA North Bay Operations and Maintenance Facility

EBDG was commissioned by WETA to enhance their North Bay maintenance facility, adding three new concrete floating piers and a deckhouse to the existing service float. This upgrade enables greater vessel maintenance capabilities and passenger loading options. Our team provided naval architecture services, designing mechanical and electrical systems, including HVAC, fire main, potable water, and bilge pump systems. We ensured compliance with Federal and State regulations, creating flexible connections for independent float motions, and optimizing the facility's functionality for WETA's operational needs.